The marking parameters of several common materials

The parameters of laser marking machine are different with different materials. According to our experience, we sorted out the marking parameters of the following materials

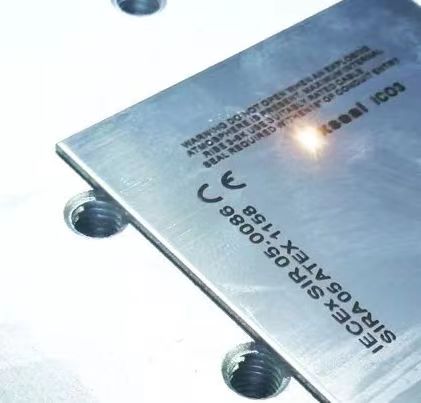

1.hardware (stainless steel, aluminum, iron, copper, electric ferry, etc.)

General laser marking: In order to achieve uniform lines and clear characters, the focal length from the edge of the lens to the surface of the product is approximately 18.5cm

If you need to make the stainless steel black, or deep carving:

A: Black: defocus method is adopted, the normal focus is about 5MM above; The line spacing should be closer, about 0.02mm, and the frequency should be slightly higher. According to the material of the product, the edge winding mode can be cancelled.

B: Deep carving: increase the power, reduce the speed, do it several times, fill it twice, fill it vertically.

2. Plastic (PC material, circuit board, oil injection, electric ferry, etc.)

PC material, line line board electric cross products such as current can not be too large, so as not to burn the material inside. In order to avoid laser is too strong, you can adjust the height of the table, the processing surface is placed in the focus of the laser below the height of 2-3 mm. Spray oil and other products, the frequency needs to be higher than hardware products, generally take a filling method, special products (such as surface spray white paint) take two filling method, one filling line spacing is dense, the other filling line spacing is sparse.

3.rubber (such as mobile phone buttons, car buttons, etc.)

Rubber products without background color: only one filling, the surface ink carving clean, keep the characters clear;

Rubber products with a base color, that is, sprayed with more than two layers of ink, just put the top layer of ink clean, exposed to the bottom layer of color (common red, yellow, white, blue, etc.), need to use two kinds of filling, frequency increase. (Rubber products generally need to be wiped with industrial sprinkling after marking.)